Battery Test

Service

ORANGE.I directly performs battery cycle tests for safety

and lifespan evaluations, which are essential during

the lithium-ion

battery research, development,

and manufacturing stages, and provides evaluation

results & data to clients.

Battery Cycle Test

What is Cycle Test?

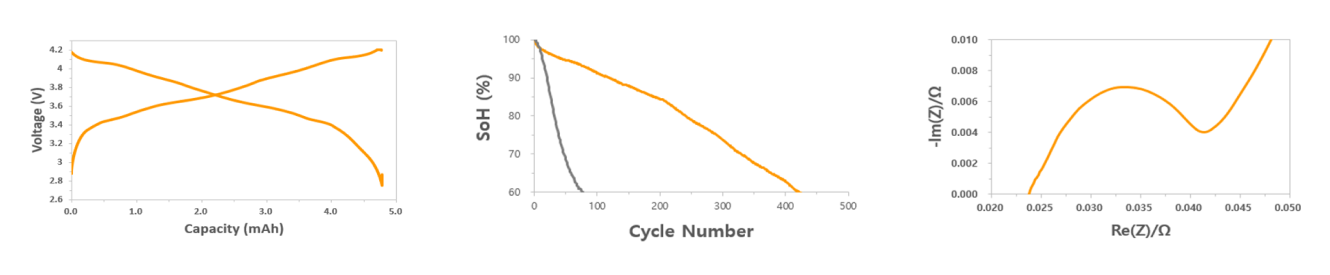

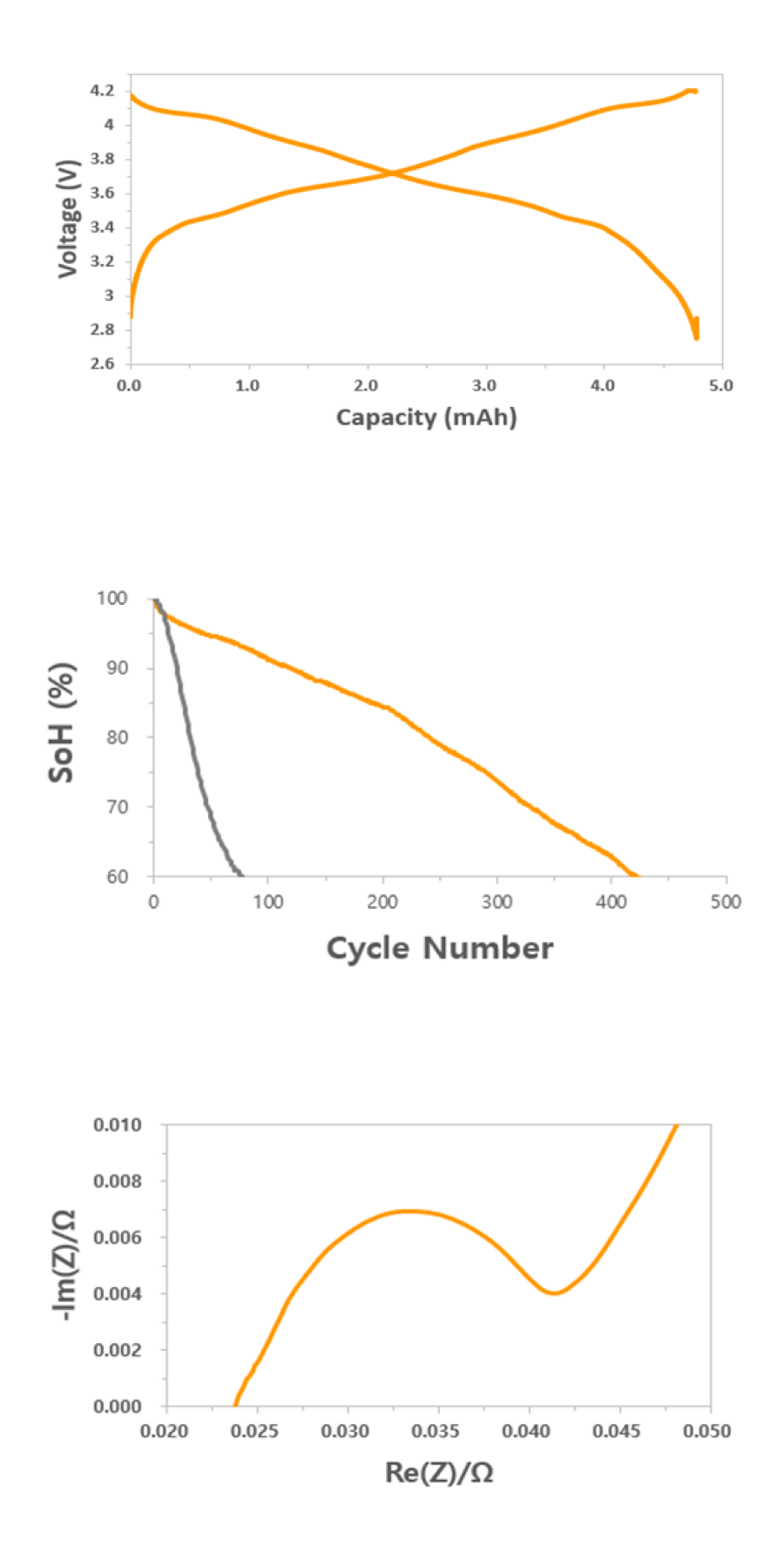

The battery cycle test refers to the task of repeating charging and discharging the battery hundreds of times using cyclers for several months

under various conditions, such as voltage, current, pressure, temperature, and rest period.

Tests generate data on battery voltage, current, capacity, internal resistance, temperature, time required, energy efficiency, impedance, etc.

for battery design verification and safety, reliability, and lifespan evaluation.

Cycle Tests in

Battery Value Chain

Why are cycle testing

services required?

-

The increased demand for secondary batteries for EVs and ESS is

expected to boost the demand for evaluation as well. -

Data distributed by department and project impedes seamless access

and usage. -

Construction, maintenance, and expansion of environments such as

evaluation equipment and SW incur high costs. -

Relying on manual data collection poses potential reliability issues,

including contamination. -

Data organization and report writing tasks are monotonous, repetitive,

and inefficient. -

It is demanding to monitor revaluation progress and real-time data.

Test Contents

ORANGE.I performs the cycle tests quickly and precisely in accordance with the clients' request through the test experts.

Our own evaluation center which located in Suwon, Korea, is equipped with facilities comparable to those of the largest battery manufacturers.

Test Process

-

Ordering & Signing

Contracts -

Establishing Test Plans

- Customer needs Analysis

- Equipment and channels Allocation

-

Warehousing Cells

- Quantity and Information Check

- Visual Inspection

- Attaching QR codes

-

Tests Performancing

- Measuring OCV, EIS, and capacity

- Performing Cycle Test

- Data Monitoring in Real Time

-

Test Result Reporting

- Supporting PC and Mobile Access

- Secured on Cloud

-

Shipment Inspection

- Quantity and Information Check

- Visual Inspection

-

Returning Cells

ORANGE.I performs the cycle tests quickly and precisely in accordance with the clients' request through the test experts.

Our own evaluation center which located in Suwon, Korea, is equipped with facilities comparable to those of the largest battery manufacturers.

Discharge Evaluation

: Capacity, Cycle, dQ/dV

: Internal Resistance (Rs, Rct, RSEI)

Cylindrical : 20A

Prismatic : 600A, 1,200A

Test temperature : -20~60℃

Voltage : ±10V

EIS range : 10KHz~10μHz

ORANGE.I performs the cycle tests quickly and precisely in accordance with the clients' request through the test experts.

Our own evaluation center which located in Suwon, Korea, is equipped with facilities comparable to those of the largest battery manufacturers.

Equipment

Cycler

| Item | Channel | Control Voltage (Accuracy) |

Current Ranges (Accuracy) |

Cell Connection | Temp. Measurement |

|---|---|---|---|---|---|

| Spec | 8 | -1V ~ 5V (±0.02% f.s.) |

20A, 1A, 100mA, 10mA (±0.05% f.s.) |

20A, 1A, 100mA, 10mA (±0.05% f.s.) |

/Channel Monitoring |

Chamber

| Item | Temp. Range | Uniformity | Controller | Heat Up Time Pull Down Time |

|---|---|---|---|---|

| Spec | -20℃ ~60℃ | ±1℃ at 25℃ | Auto-tuning controller |

Average 2℃ /min Average 1℃ /min |

EIS

| Item | Current | Voltage | Impedance Range | Cell Connection |

|---|---|---|---|---|

| Spec | Range : ±10㎂~20A Resolution : 0.004% Current accuracy : <40mA |

Range : ±2.5V, ±5V, ±10V Resolution : 0.0015% |

10KHz~10μHz Rise time and fall time : 25~60㎲ |

5 Probe Type |

Technology

ORANGE.I's proudful self-developed secondary battery analysis solutions, built on a secured cloud platform,

allows for real-time processing of massive volumes of assessment data while ensuring data stability and security.

Features

By outsourcing technically simple but time-consuming test works to ORANGE.I's specialists,

increase your battery R&D efficiency and make productivity your top priority.

-

Rapid EvaluationQuick and accurate test for different products under various conditions,

such as temperature, voltage, and current, through professional evaluation facilities -

Automized Data ProcessingAccurate insights offering and decision-making facilitating supported by

ORANGE.I’s battery data specialized analysis solutions -

Physical Risk EliminationReducing the risk of accidents or disasters such as fire or explosion that may occur

during evaluation and the resulting prevention costs (*by Risk detection solution) -

Easier Data AnalysisCustomizable data monitoring such as real-time evaluation status queries,

data visualization, and automatic report generation -

Optimal design partnerImproving the efficiency of design work through analyzing causes of defects based

on evaluation data for each material and design -

Data Asset BuildingCentralizing and turning dispersed assessment data into cloud-based

corporate assets