Analysis Service

ORANGE.I provides accurate test analysis and

consulting based on scientific and

objective data.

With over 30 years of experience in the industry

and technical

knowledge, our analysis experts

are here to support you.

Analyzing battery cell material properties, fine

sample components such as

foreign substances,

diverse organic and inorganic materials, and

performing

professional analysis on product

defects and failures

Battery Cell

& Raw Materials

By analyzing the components and structural properties of battery materials, parts, and cells helps better understand

battery performance and lifespan. ORANGE.I possesses core technologies that analyze lifetime characteristics,

changes in material conditions inside cells, and electrochemical properties.

-

4 Major Materials Analyzing

Analyzing the composition, shape, and structure of positive and negative electrode active materials, separators, and electrolytes to identify material type, mixing ratio, additive components, and component distribution; leveraging that information in material development; observing changes in state before and after deterioration; identifying the cause of deterioration; and applying it to improvement activities.

-

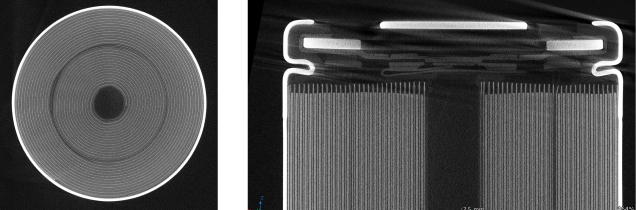

Non-destructive Analysis of Battery Cells

Visually analyzing the structure, defects, material distribution, and structural changes inside the battery through cutting-edge 3D CT technology based on X-ray transmission technology and indirectly verifying the internal state of the cell through electrochemical analysis.

-

Battery Parts Analysis

Examining the composition, structure, and surface treatment of materials used as parts, such as aluminum base, copper base, can, tab, pouch, etc., understanding their distributions, and defining the different physical attributes necessary for component materials.

By analyzing the components and structural properties of battery materials, parts, and cells helps better understand

battery performance and lifespan. ORANGE.I possesses core technologies that analyze lifetime characteristics,

changes in material conditions inside cells, and electrochemical properties.

Analysis Cases

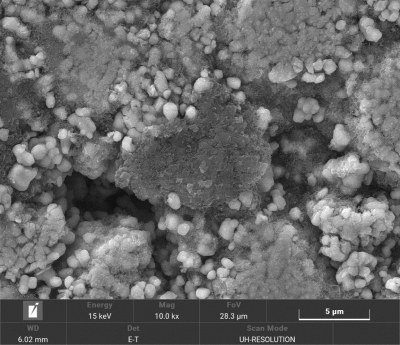

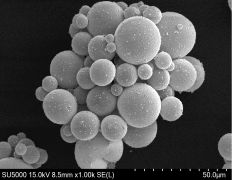

Cathode electrode

surface shape

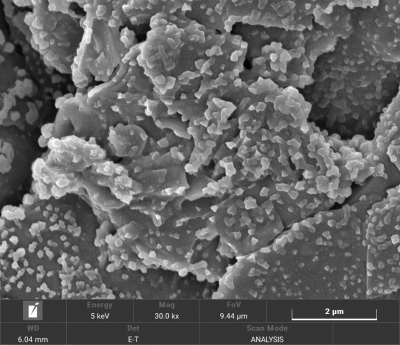

Anode electode

surface shape

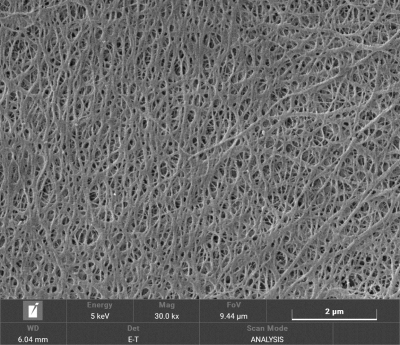

Separator surface

shape

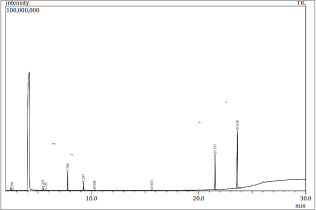

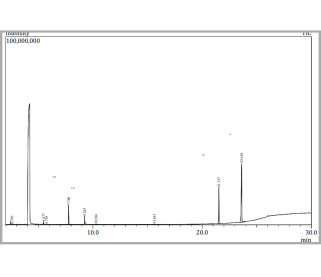

Main components of the

electrolyte in the cell

4 Major Materials Analysis Cases

3D transmission shape of a cylindrical cell

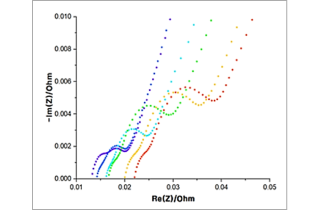

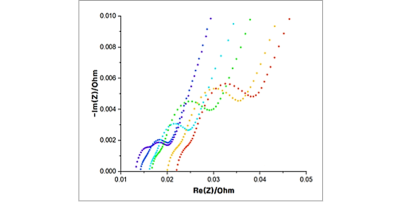

Impedance change according to life cycle

By analyzing the components and structural properties of battery materials, parts, and cells helps better understand

battery performance and lifespan. ORANGE.I possesses core technologies that analyze lifetime characteristics,

changes in material conditions inside cells, and electrochemical properties.

Analysis Cases

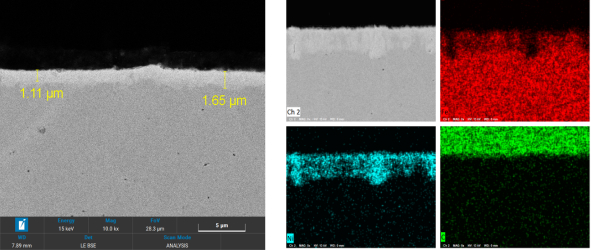

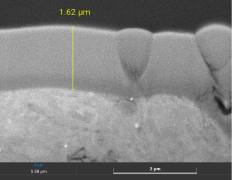

Ni plating layer distribution on the can surface

Bonding phase of the surface coating layer

Part material analysis example

ORANGE.I is equipped with precise sample pre-treatment technology and data interpretation technology to analyze the components of foreign substances

at the level of ㎛ to ㎜ and determine the source of inflow during processes or products such as batteries, semiconductors, food, and pharmaceuticals.

Analysis Items

Foreign substances injected during processes: checking the composition of extremely tiny foreign substances retained in the process.

Foreign substances on the product surface: assessing foreign substances remaining on the product surface and discovering the source of inflow using comparative assessment and comparison

Analysis Process

-

Sample

PretreatmentSeparating foreign substances and sampling

-

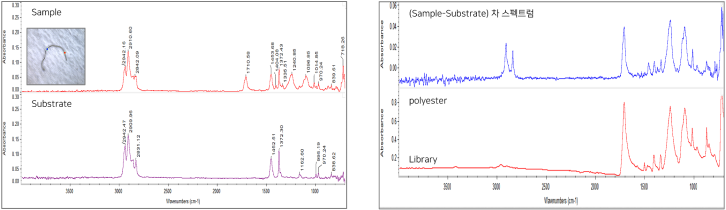

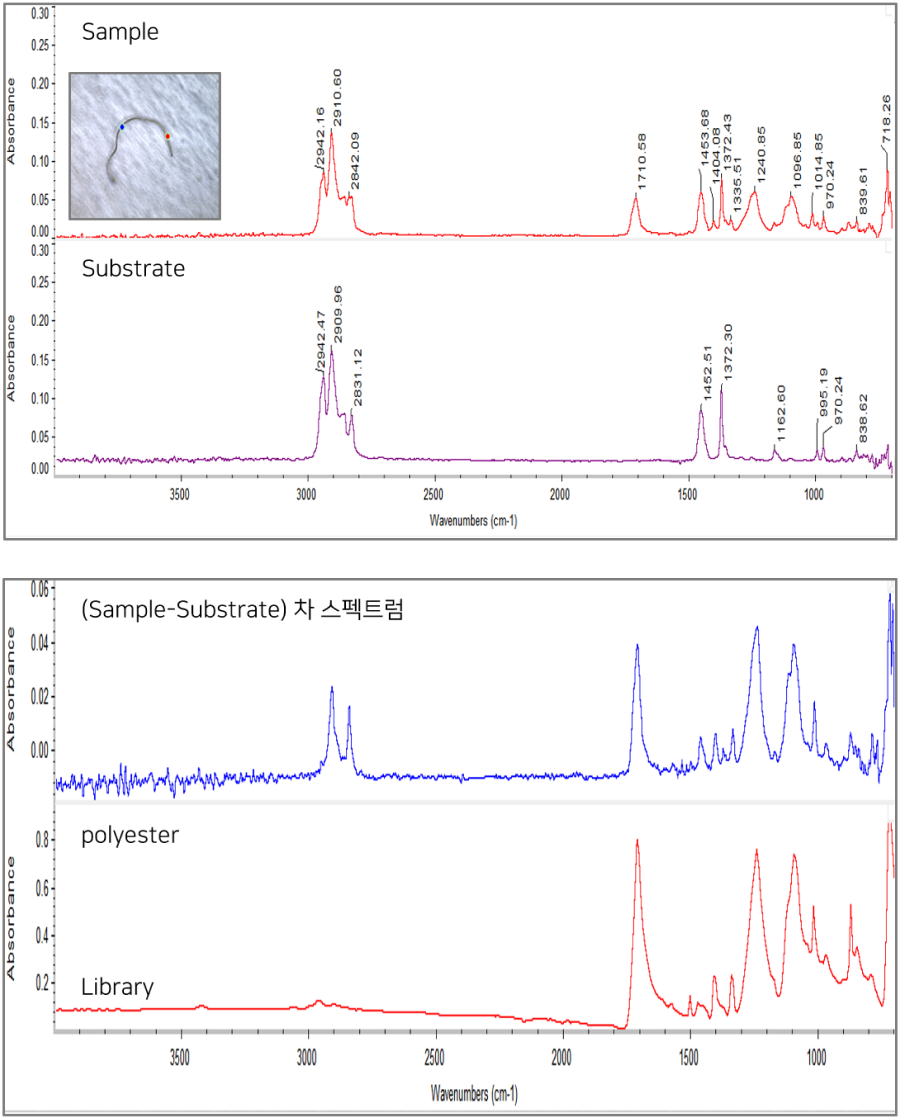

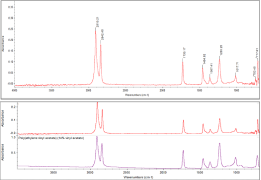

Organic Material Analysis

(micro-FTIR)Analyzing materials such as plastic, rubber,

fiber, and natural materials -

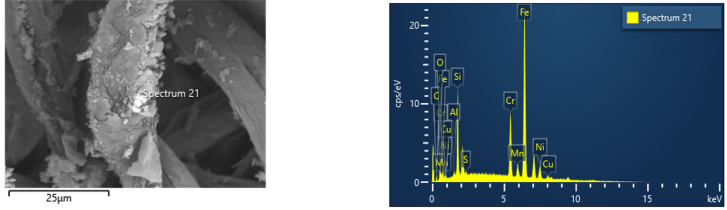

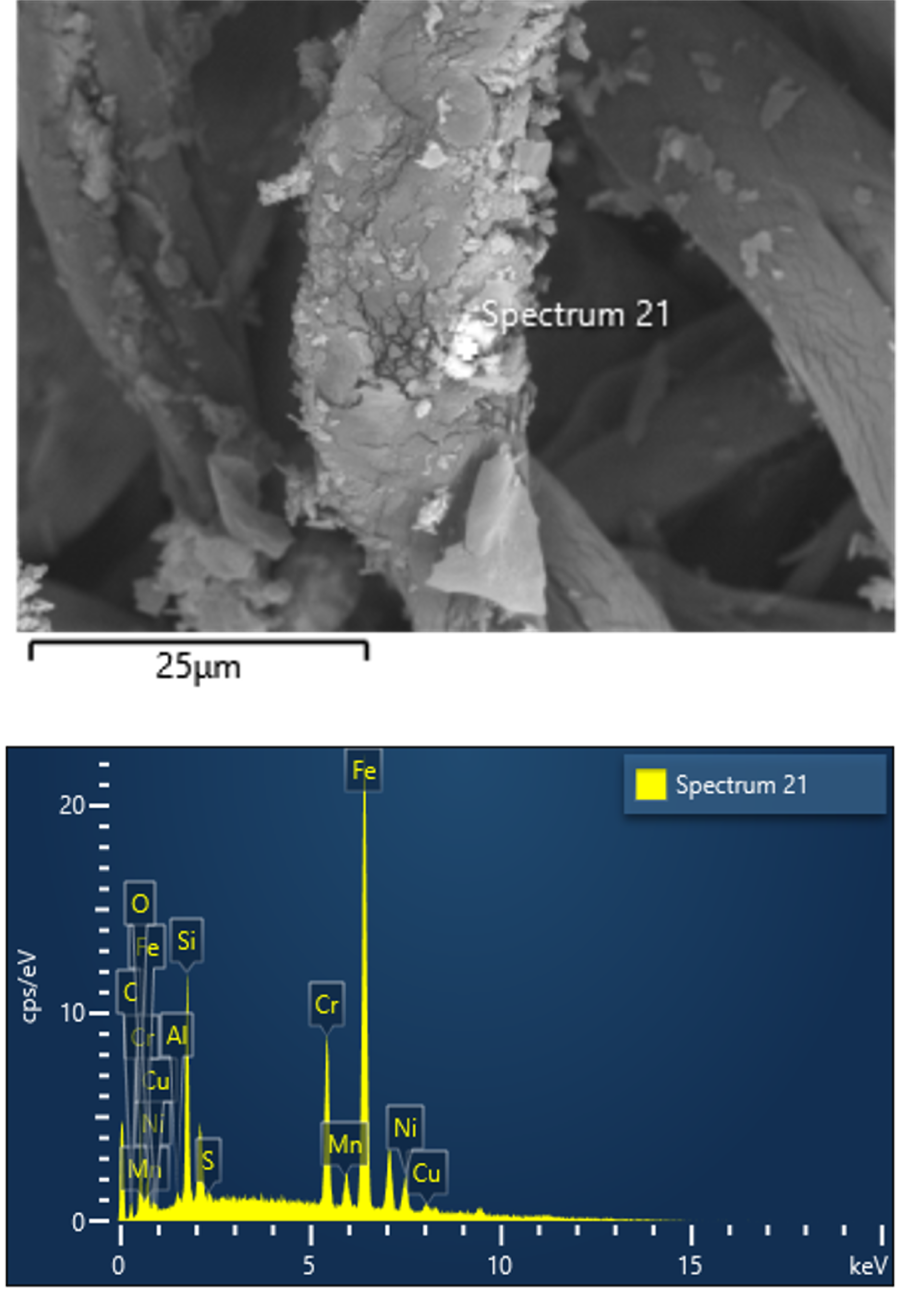

Inorganic Material Analysis

(FE-SEM/EDS)Analysis of materials such as

metal, glass, ceramics, Etc. -

Interpretation of

comprehensive resultsDetermining final results and

preparing the test report

ORANGE.I is equipped with precise sample pre-treatment technology and data interpretation technology to analyze the components of foreign substances

at the level of ㎛ to ㎜ and determine the source of inflow during processes or products such as batteries, semiconductors, food, and pharmaceuticals.

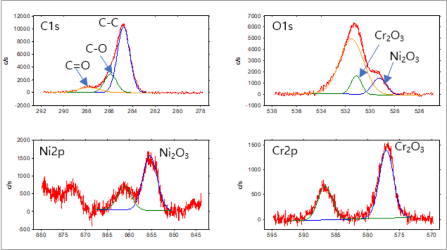

Analysis Cases

Analysis of foreign substances in the form of fibers of hundreds of ㎛ supplied from outside

Analysis of foreign substances by collecting tens of ㎛ of foreign substances within the process

Organic & Inorganic

Materials

The composition, structure, and physical properties of organic and inorganic materials are essential factors in determining

product quality. ORANGE.I provides optimal analysis data by choosing an analysis approach that is suited for the customer's needs

and obtaining deep and broad data.

Organic & Inorganic

Material Analysis

| Item | Description | Example | Major Analytical Equipments |

|---|---|---|---|

| Organic | Chemical substances produced by living things that are generally classified as organic if they contain carbon compounds |

sugars, proteins, fats, hydrocarbons, plastics, rubber, fibers, natural substances, etc. |

FT-IR, Raman, GC-MS, NMR, XPS, Tof-SIMS, TGA, DSC |

| Inorganic | Any elements that are not organic | Minerals, metals, ceramics, glass, etc. | ICP-OES, ICP-MS, IC, XRF, XRD, XPS, SIMS, SEM-EDS, TEM |

The composition, structure, and physical properties of organic and inorganic materials are essential factors in determining

product quality. ORANGE.I provides optimal analysis data by choosing an analysis approach that is suited for the customer's needs

and obtaining deep and broad data.

Analysis Cases

Investigating the organic materials

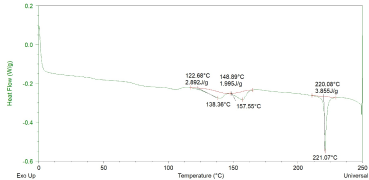

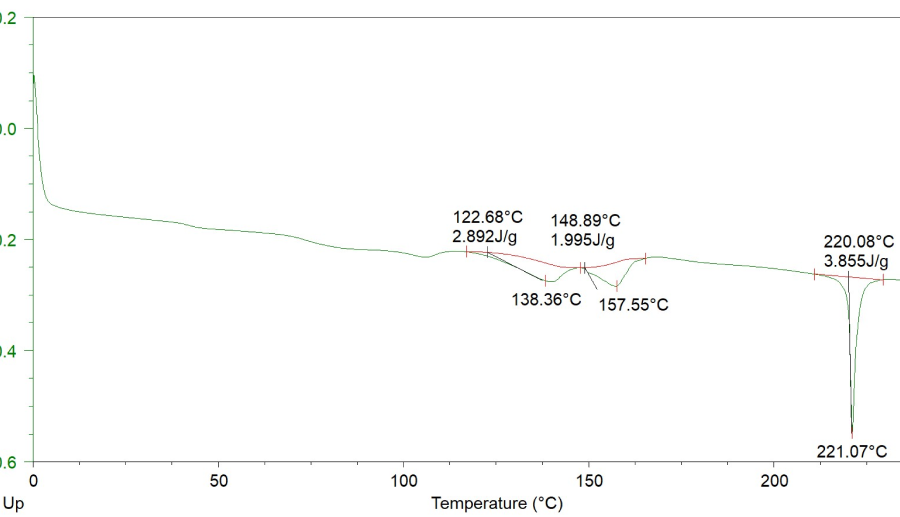

Verifying the thermal characteristics of the pouch

Detecting trace organic substances

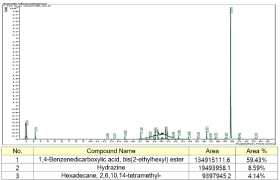

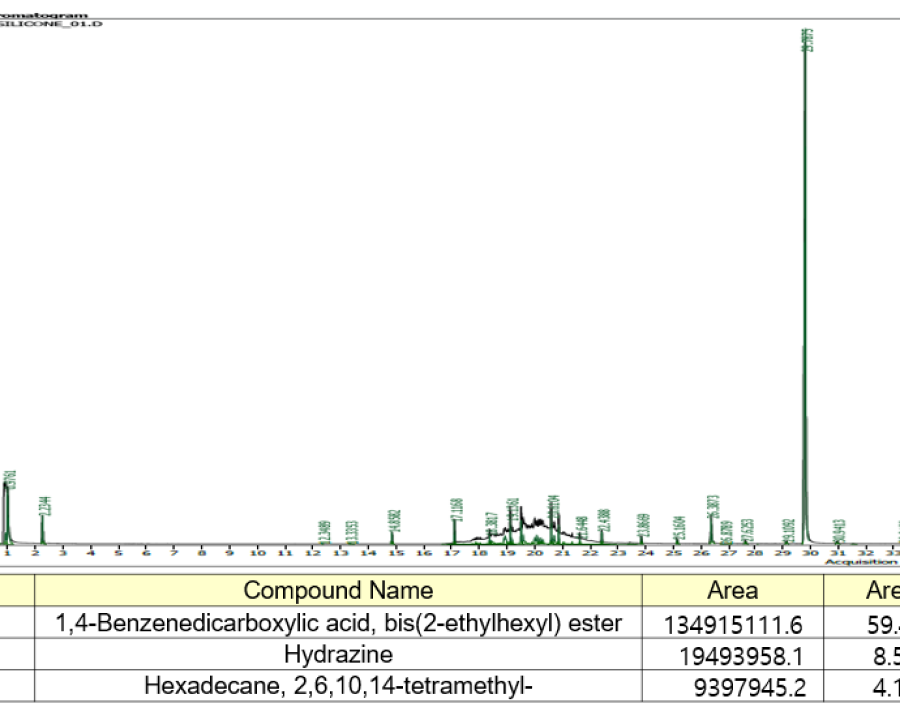

remaining in the silicone

Analysis of organic materials

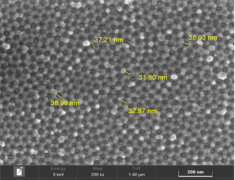

Observing the surface shape

of ceramic particles

Watching the cross-section of the plating

layer formed on the metal surface

Checking the high-magnification

shape of the metal surface

Analysis of inorganic materials

Failure Analysis

ORANGE.I analyzes the causes of unexpected failures and defects that occur in products and parts as results of

environmental or physical stress. We deliver effective solutions to pressing challenges by maintaining frequent

communications with our consumers.

Failure Analysis

Process

-

Occurrence of

an issue -

Definition of

the problem- Defining defect phenomenon

- Discussing with customer

-

Establishment of

hypothetical scenario- Setting up a hypothesis

- Deciding the analysis method

-

Validation of

analysis and factors - Calculating analysis data

- Verifying significant

differences from hypothesis

-

Making

final conclusions- Producing final results

- Proposing improvement plans

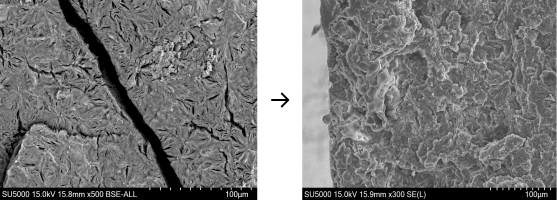

Analysis Cases

Analyzing the phenomenon of plastic breakage defects

and evaluating the material, hardness, etc. to determine the cause

Analyzing the corrosion caused by a defective pin hole

on a metal surface and identifying the cause